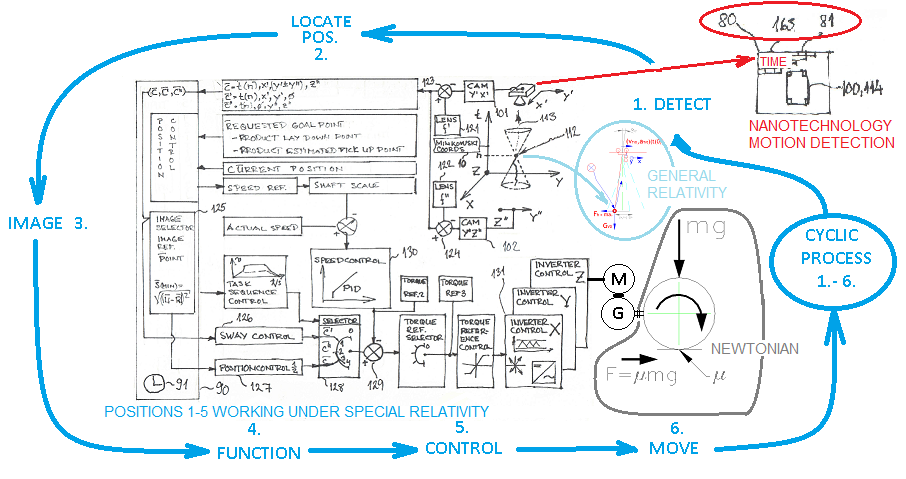

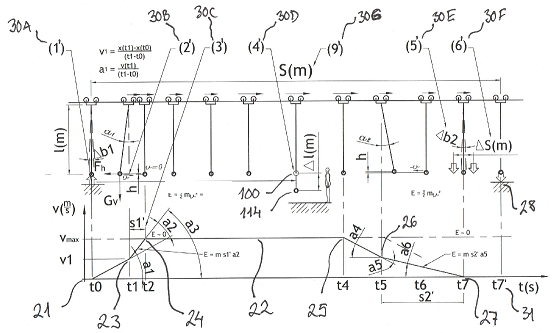

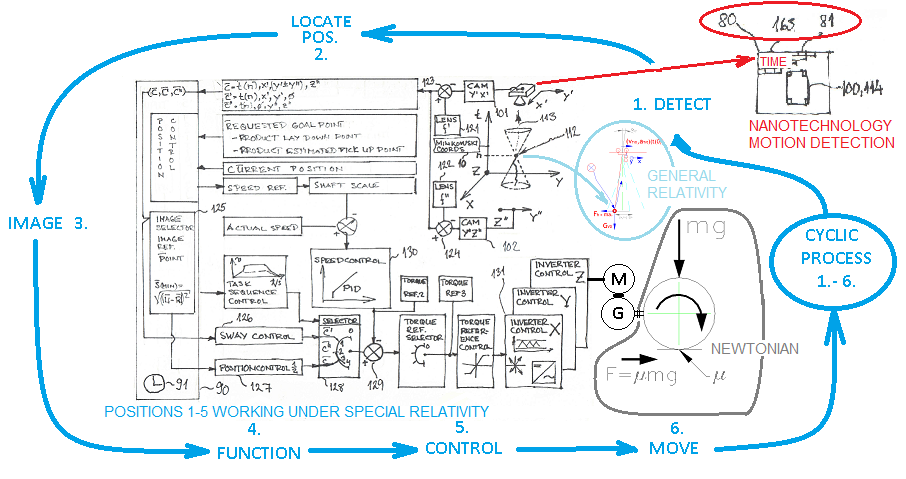

Picture 1:Event [112], two observers and machine motion control system

Closed loop motion control from event (112) to motion control 131 and motors

Newtonian friction force F=μmg

By looping control cycle, Newtonian gravity acceleration dependent contant 'g' in force F will ignored.

Hole process loop 1.-5. measure and control motion under rules of special relativity.

Motion control will only improve when prosess calculation capacity will improve.

Calculation capacity is cheap resource compared to huge material flow

and the energy needed to lift, transfered and put down it.

Furthermore, optic machine vision technology provide also other 'free' benefits which improve safety and reliability like visual view.

We could drive system more in the edge, when we have friction based motion drive.

When system calculated motion speed will not achieved, motion control system internal acceleration and deceleration may be readjusted.

Colored area show the scope of technology to be used.

Relativity theories cover all other but friction between wheel and track.

When control is looping the use of NEWTONIAN gravity theory is not used for motion control.

Newtonian tehnology will used for material strength dimensioning on which relativity do not provide solutions.

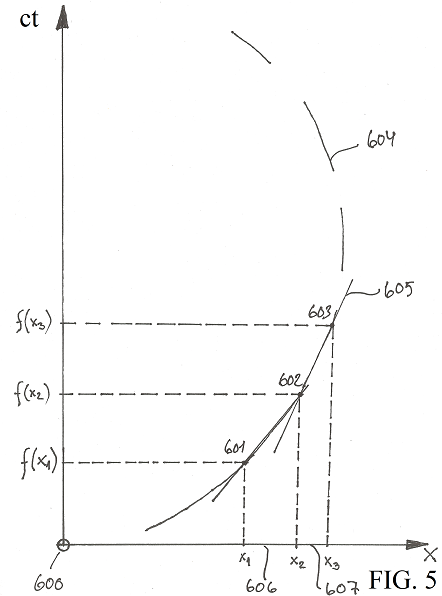

When motion detection will be done by image data and accurate time datafusion. E.g. with 'standard' 100ns accuracy,

motion detection pointo-to-point distance resolution accuracy (x(1)-x(0)) fullfill NANOTECHNOLOGY technology limits.

Cyclic control process items 1.- 6. time is dependent on calculation capacity.

When cycles run item steps (1.-6.) inside the time scope of interest (less than 100ms and TIMER resolution 100ns),

the sway motion controllability will be the most efficient.

Descriptions: NEWTONIAN = area that neither special relativity nor general relativity do not cover.

80=image data captured,81=individual pixel map, 100,114=object under gravity and acceleration forcies, 163=accurate time when observer receive image, 101=observer 1 (camera), 102=observer 2 (camera), 112=light reflecting event on objects surface,

113=light waves (info about the event), 121,122=zoom cam lens, 123,124=zoom lens position control, etc.

In item 1. light waves (113) carry sway position information with several parallel light waves where as control system items 2.-5. transfer data in a form of serial data.

The serial data transfer speed is always slower than the parallel data transfer speed and therefore captured image (80) with a time stamp (163) solve several problems with data transfer delays.

|